WorkShop Procedures

Job Registration

All jobs received at our workshop are booked into our job card system with full detailed customer information and Job information. The job card system is created with a job reference number against each job received at our workshop.

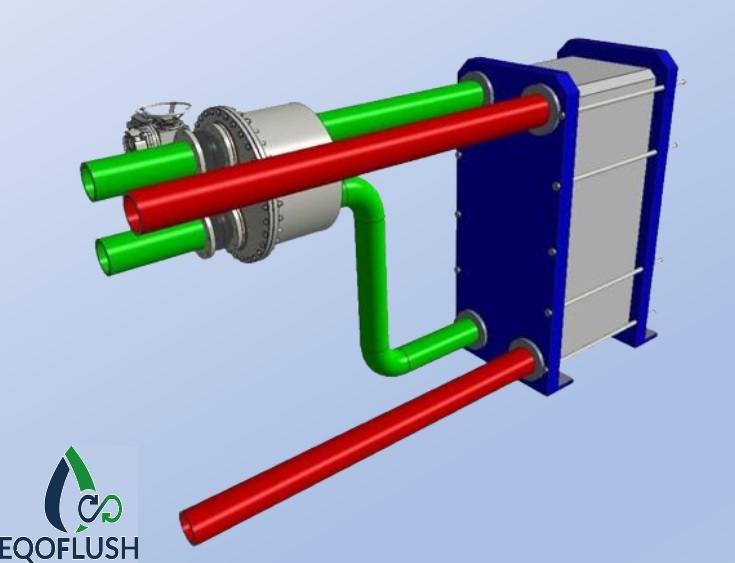

Cleaning & Pressure test

No sooner the unit is received at our workshop, we conduct a full inspection of each and every component of the unit to determine the metal components and ensure the right use of chemicals for an initial cleaning and pressure testing. Our initial pressure test isto determine the condition of the unit is suitable for repair or remanufacture. This initial pressure test saves time for both parties, the service provider, and our valued customer.

Reporting

Upon completion of our initial clean and pressure test, the workshop supervisor will report to the administration the condition of the unit. Our administration will immediately contact the concerned customer with the full details and conditions of the unit.

Clean,Repair & Remanufacture process

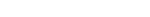

The unit is first inspected to determine the metal components so as to enable us to insert it into the right chemical tank. The supervisor will assess the time required for the unit in the chemical tank and accordingly instructs the technicians to move it into the servicing bay for a complete pressure wash.

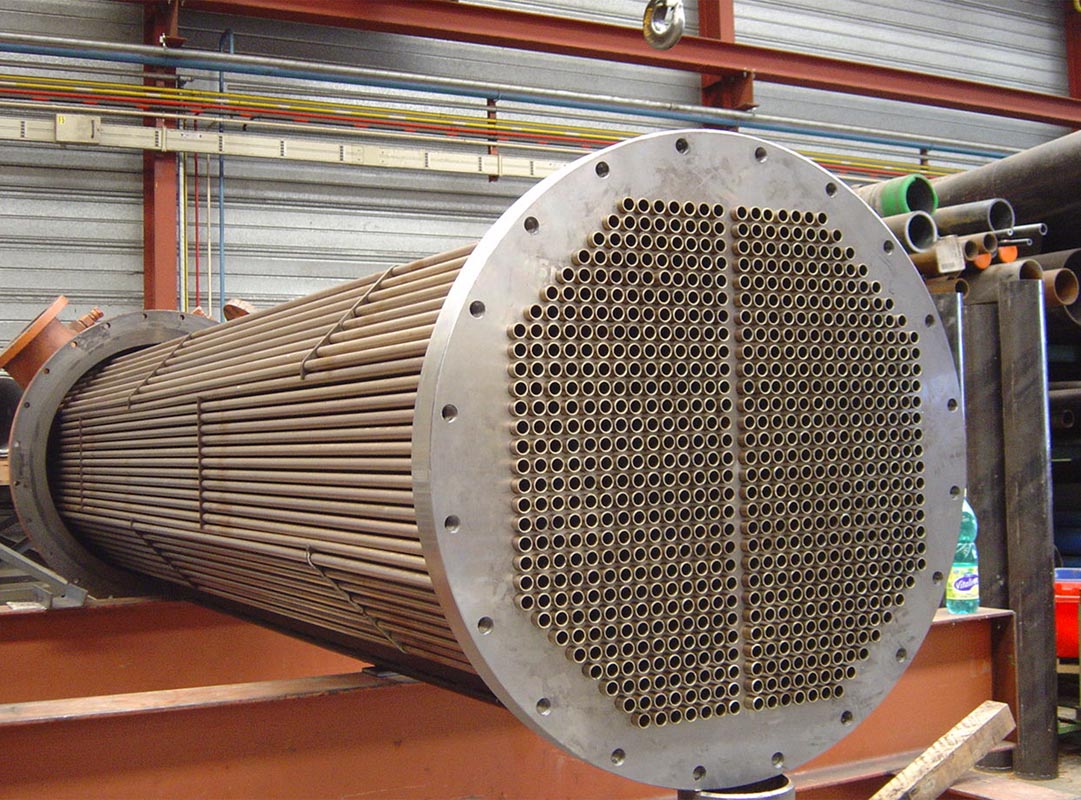

A well-qualified technician will run a pressure test to determine the damage to the unit. The technician will then determine the suitable repair process and material usage. Plug the leaking tubes, expand the tubes, repair the leaking tubes, Carry out the repair using brazing rods like silver, brass, lead, etc., All units for repair are fitted with new ‘O’rings, gaskets, nuts & bolts based on the existing material on the unit.

Units reported by the workshop supervisor to be beyond repairs are notified to the customer. A revised quotation is provided to the customer and after formal approval, the unit goes into production.

Packing & Delivery

All finished units are well packed to ensure the unit is well protected from any external damage and any kind of debris entering the unit. The units are safely lifted by our workshop crane and well placed into a truck for delivery.

Pressure test certification

All remanufactured units are issued with a pressure test certificate and a copy of the same is handed over to our valued clients.

Records

Each job carried out in our workshop is maintained as a job folder with a full track record.

.jpg)

.jpg)

.png)

.jpg)